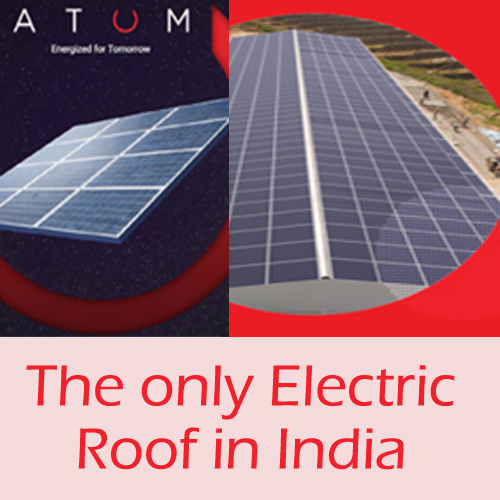

In simple terms ATUM is ROOF + SOLAR integrated in a single product with very important attributes that are not available in traditional solar panels such as:

Module Mounting Structures are designed and engineered for each customer’s site specific conditions to minimize the field installation labor and require no filed welding, drilling or other on-site fabrication.

Pasumai is manufactured under controlled conditions, in “State-of-the Art” manufacturing systems, adhering to safety and superior quality parameters.

Selecting the best type of roof truss is quite challenging. Functionality and aesthetic conditions lead to the considerations of the type of roof truss that you will select. Costs can vary considerably, but there are ways to keep expenditures low.

A roof truss can make sense when designed to address considerations that often trigger expensive, special building code requirements. You can realize these advantages when using a truss: